The treatment of large bone injuries continues to be challenging partially due to the limited quantity and quality of bone replacement materials.

We developed porous biodegradable iron (Fe)-based scaffolds using extrusion 3D printing technology and comprehensively studied the scaffolds characteristics, while progressively aiming to fulfill all the material requirements for use as bone substitutes.

Iron-based alloys and composites have been developed as a group of biodegradable bone-substituting biomaterials.

First, we fabricated porous Fe scaffolds and thoroughly examined the characteristics of their porous structure upon 3D printing and sintering. We then investigated their in vitro biodegradation behavior, electrochemical responses, uniaxial compressive mechanical properties along with in vitro biodegradation, and cytocompatibility. We recognized the strong need to enhance the biodegradation rate, improve the magnetic behavior, and biocompatibility of the material.

https://doi.org/10.1016/j.actbio.2020.11.022

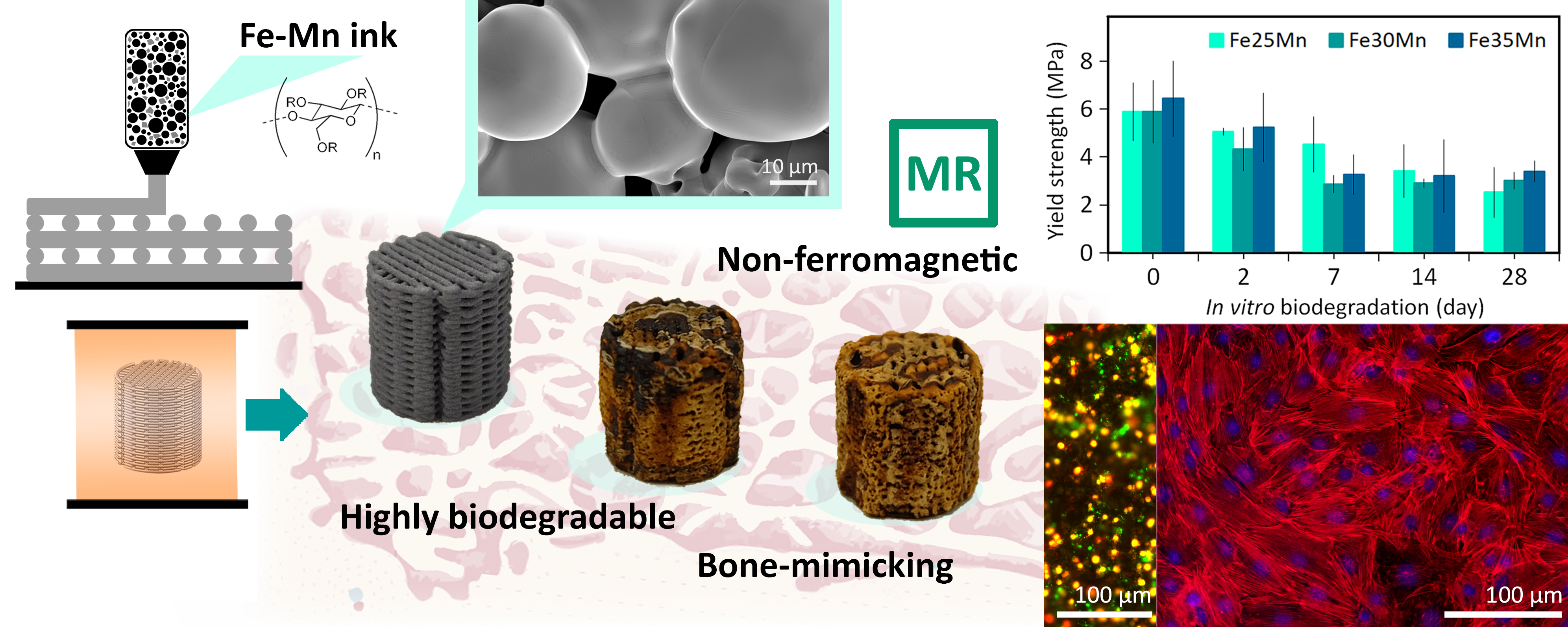

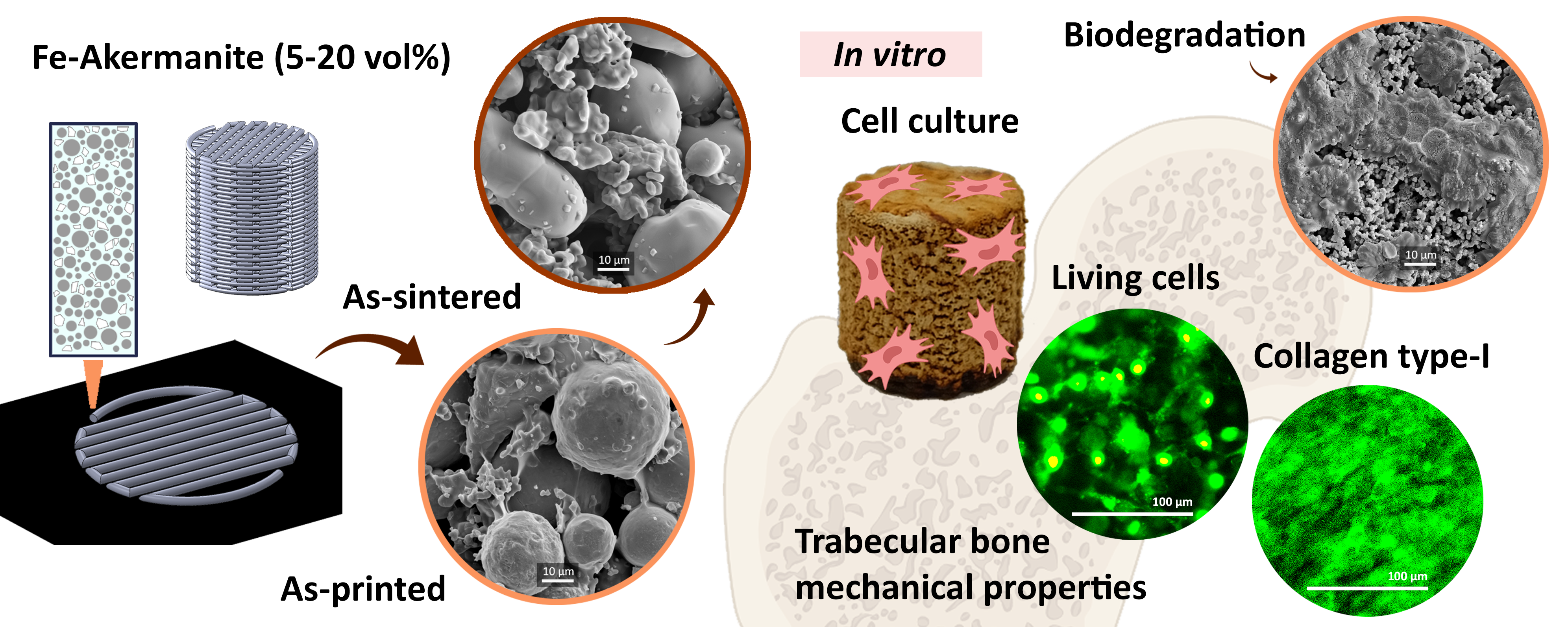

We modified the material chemistry of pure iron to resolve the issues concerning the ferromagnetic behavior and lack of bioactivity. We implemented the multi-material 3D printing strategy by alloying Fe with manganese (Mn) and reinforcing Fe with akermanite (Ca-Mg-Si-based bioactive ceramics) and thoroughly evaluated the performance of the scaffolds, including the magnetic behavior and osteogenic potential.

https://doi.org/10.1016/j.actbio.2021.07.042

https://doi.org/10.1016/j.actbio.2022.06.009

With the expected benefits gained individually from alloying with Mn and compositing with akermanite, we developed the FeMn-akermanite composite scaffolds, taking advantage of the multi-material capacity of extrusion 3D printing. Our results clearly demonstrated that the extrusion 3D printed porous FeMn-akermanite scaffolds could fulfill all the requirements for bone substitution in vitro.

https://doi.org/10.1016/j.actbio.2023.03.033